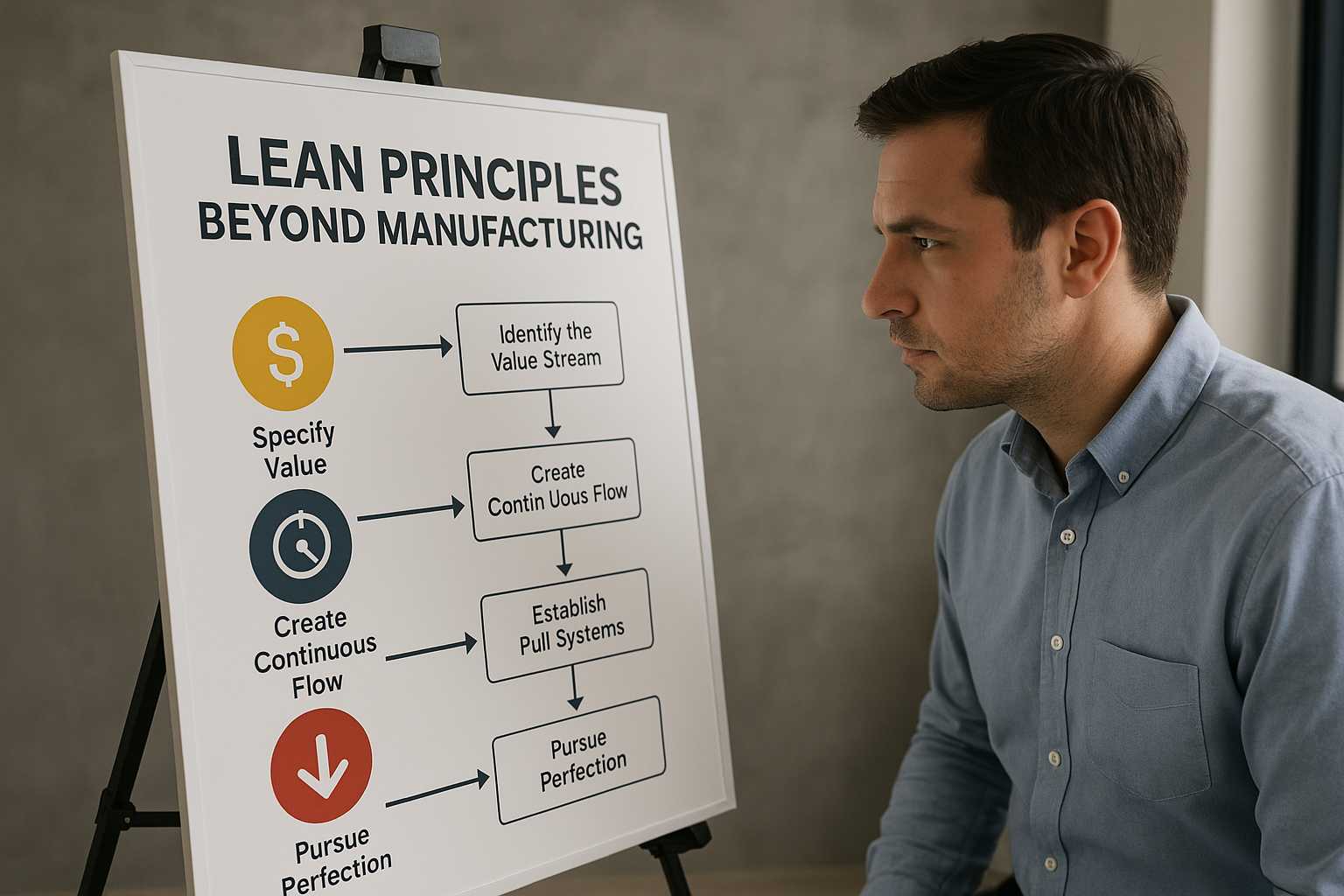

Lean Six Sigma HR Consulting for Large Corporations: Driving Operational Excellence Lean Six Sigma methodology offers an effective approach for HR departments struggling with process inefficiencies and quality issues. The methodology aims to achieve just 3.4 defects per million opportunities. This systematic approach changes how major corporations handle their human resources operations. Perfect execution remains...

235 Dixon Road Unit 106, Etobicoke, ON, M9P 2M5 Canada

+1 (800) 799 5491