Lean principles lean principles pack more punch outside manufacturing than within traditional factory settings. Toyota’s 1950s manufacturing methodology has grown into something much bigger – reaching far beyond assembly lines and production floors.

Success stories keep piling up across healthcare, financial services, and government sectors. Picture this: an auto parts distributor pocketed $600,000 through smart implementation of lean principles. A financial institution slashed their loan processing timeline from three weeks to just 24 hours.

Military organizations first adapted these principles for service industries in the early 2000s. Healthcare and financial services quickly followed suit. Modern businesses across every sector now use lean principles to spot waste, streamline operations, and boost customer value.

Ready to unlock the power of lean principles for your organization? This guide shows exactly how to transform operations and achieve measurable results – no factory floor required.

Understanding Lean Principles Beyond the Factory Floor

Lean principles strip away waste while maximizing value across business processes. What started as Toyota’s manufacturing playbook now drives success in countless industries and business functions.

What are lean principles?

Think of lean principles as your waste-detection radar. These principles emerged from Toyota’s Production System (TPS), but they’re much more than just a toolbox. They represent a complete business philosophy focused on cutting waste, shrinking costs, and boosting quality.

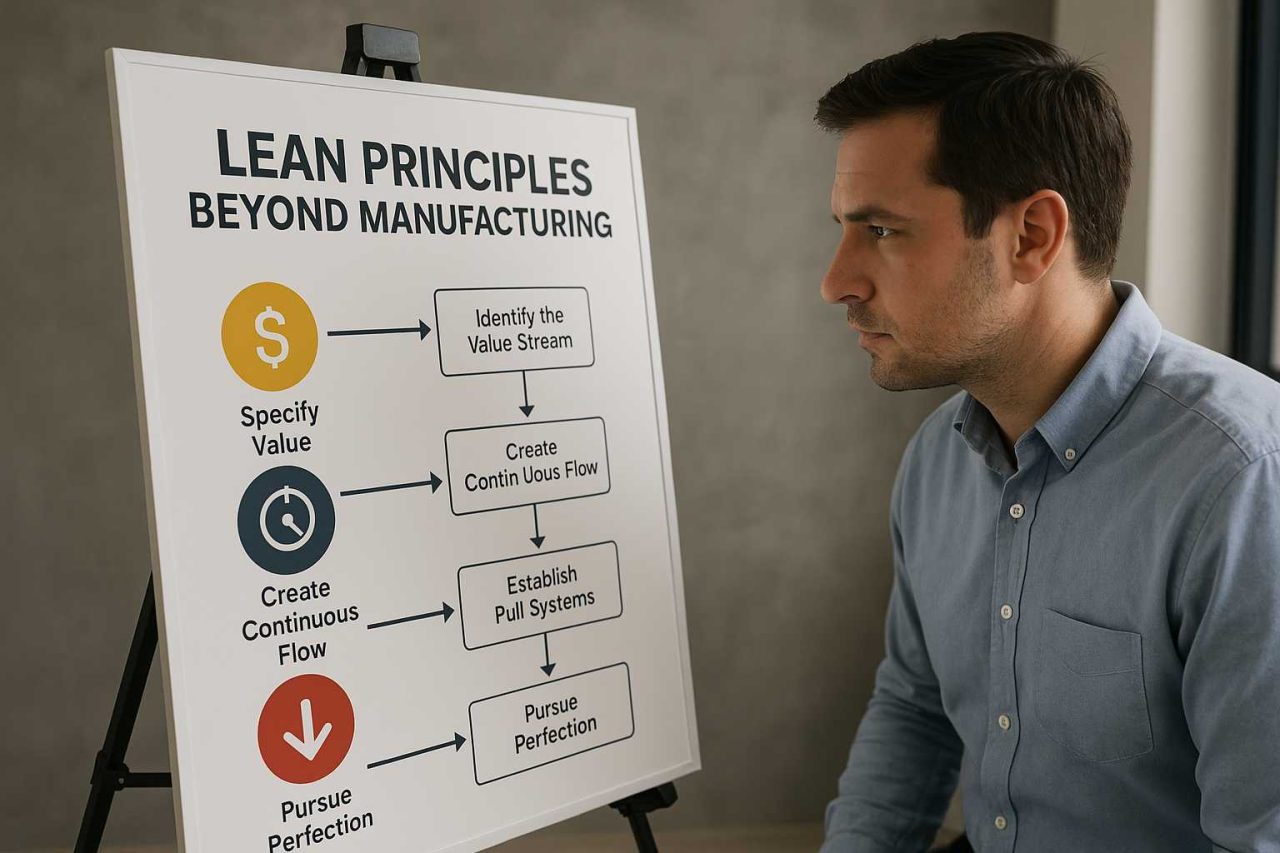

Womack and Jones mapped out five core principles in their 1996 “Lean Thinking” book:

- Specify value from the customer’s perspective

- Identify the value stream and eliminate waste

- Create continuous flow by removing interruptions

- Establish pull systems where customers drive production

- Pursue perfection through continuous improvement

The evolution of lean thinking

The lean journey started small but grew mighty. John Krafcik coined the term “Lean” in 1988 while studying Toyota’s super-efficient production system. James Womack’s 1990 book “The Machine That Changed the World” turned these ideas into a global movement.

Military organizations first grabbed these principles around 2000. Healthcare and financial services quickly jumped on board. Smart businesses realized something game-changing: waste lurks in every process, no matter the industry.

Core lean principles meaning in non-manufacturing contexts

Service industries face unique challenges with lean principles. The waste isn’t sitting on a factory floor – it’s hiding in workflows and processes. Software teams, for example, tackle tricky problems like uncertain tasks and invisible processes.

Key ways businesses adapt lean principles beyond manufacturing:

- Making hidden work processes visible

- Spotting eight types of service waste

- Creating standard steps for variable tasks

- Setting clear quality standards for knowledge work

Toyota’s 2001 approach added something crucial: people matter as much as processes. Their dual focus on continuous improvement and respect for people helps lean principles work everywhere from tech startups to government agencies.

Identifying Waste in Service and Knowledge Work

Spotting waste in service and knowledge work feels like finding invisible leaks in a pipeline. Factory waste jumps out at you – picture defective parts or unused inventory. But service industry waste? That’s trickier to catch.

The 8 wastes in non-manufacturing settings

Service businesses face their own flavor of waste:

- Defects – Wrong data entries, mixed messages, or half-baked information causing do-overs

- Overproduction – Those dusty reports nobody reads or meetings that should’ve been emails

- Waiting – Approval bottlenecks or computers taking forever to respond

- Talent underutilization – Smart people stuck doing basic tasks

- Transportation – Digital paper pushing or too many department handoffs

- Inventory – Email mountains, decisions in limbo, task backlogs

- Motion – File hunting expeditions or clicking through endless menus

- Extra-processing – Using sledgehammers to crack nuts or getting five approvals when one would do

Process mapping for service workflows

Process mapping puts your workflow under a microscope. Teams see exactly where work flows smoothly and where it gets stuck. Most service waste hides in handoffs between team members, not in individual steps.

Good process maps boost efficiency, clear up communication fog, tighten quality control, and light the way for smart decisions. Building one means setting clear boundaries, gathering intel from everyone involved, putting steps in order, and drawing it all out.

Value stream mapping for information flow

Value stream mapping (VSM) tracks every step from customer request to final delivery. Manufacturing folks invented it, but service teams love it for exposing information bottlenecks.

VSM shows how raw ideas become customer gold in knowledge work. It connects information dots to material results and helps managers zoom out to see the whole picture. Think of it as your waste-hunting GPS – it doesn’t just show the waste, it leads you straight to the source.

Implementing Lean Tools in Different Sectors

Smart organizations squeeze gold from lean principles far beyond factory walls. Real-world success stories prove lean thinking solves unique challenges across industries.

Lean principles in healthcare

What happens when hospitals think lean? Magic. Virginia Mason Medical Center rolled out a Patient Safety Alert system and watched liability claims drop 74% between 2005 and 2015. ThedaCare pulled a brilliant move – they moved supplies and meds right into patient rooms. Result? Nurses spent 70% more time with patients. Denver Health’s Eastside Clinic got clever too. They paired up maternal and infant appointments, slashing no-shows from over 50% to just 15%.

Applying lean in financial services

Money moves differently than widgets, but lean principles still pack a punch in finance. Top banks boost productivity by 20-25% using lean methods. One international bank built cross-functional teams that cut break age by almost 20% and slashed related risk by more than 50%.

Boston Consulting Group’s research shows banks going lean typically score:

- 15-25% better overall efficiency

- 30-60% faster cycle times

- Way fewer errors

Lean for government and public services

Canadian government folks got creative with lean. They built an e-platform showcasing over 50 improvement projects from 39 departments and agencies. Tax dollars stretch further while core services stay strong. Washington State’s lean program? Every CAD 1.39 invested returns CAD 6.27 in taxpayer value.

Lean in education and non-profits

The School District of Menomonee Falls turned lean into a team sport. Everyone from principals to classroom teachers hunts for problems and fixes them with improvement tools. Non-profits love lean too – it helps them juggle changing priorities and set crystal-clear goals despite tight resources. Best part? These organizations keep laser-focused on their mission while making every dollar count.

Measuring Success and Continuous Improvement

Want your lean principles implementation to stick? Smart measurement systems make the difference between real improvement and just pushing waste around.

Establishing meaningful metrics

Picture two types of performance indicators – leading and lagging. Lagging indicators tell you what happened yesterday, while leading indicators show what’s happening right now. Smart organizations spot problems within hours using leading indicators, instead of discovering surprises in quarterly reports.

SMART metrics (Specific, Measurable, Attainable, Relevant, Timely) keep improvement efforts on track. Top lean organizations zero in on 4-5 key numbers tied straight to strategic goals. Most track what we call QDIP metrics – quality, delivery, inventory performance, and productivity.

Creating visual management systems

Numbers tell stories better when you can see them. Great visual systems include:

Real-time dashboards that light up improvement opportunities like a Christmas tree. Teams spot issues fast and jump on fixes quickly.

SQDCP boards track Safety, Quality, Delivery, Cost, and People all at once. Think of them as your operation’s vital signs monitor.

Here’s a pro tip: stick with physical boards over digital displays when possible. Physical boards create natural gathering spots where teams and leaders hash out problems face-to-face. Plus, manually updating numbers helps people really feel the metrics.

Building continuous improvement cycles

The Plan-Do-Check-Act (PDCA) cycle works like a compass for lean organizations. Each turn points toward better performance through systematic change.

Transparency fuels an improvement culture. Public goals cascading through the organization ensure everyone knows their part in the bigger picture. Clear progress tracking keeps both frontline teams and management in the loop.

Remember this: lasting improvement means changing habits, not just processes. Organizations that get this right transform step-by-step, day-by-day – no magic wands required.

Conclusion

Lean principles shine brightest outside the factory floor. Healthcare giants, financial powerhouses, government agencies, and schools prove it daily through real results.

Look at Virginia Mason Medical Center cutting liability claims by 74%. Watch Canadian government teams streamline public services. These wins tell a clear story – lean thinking works anywhere smart people put it to work.

Success boils down to two things: measuring what matters and sticking with it. Teams that track the right numbers, use visual management tools, and keep pushing for better results leave their competition in the dust.

The magic? Lean principles target something universal – cutting waste while building value. Any process in any industry can benefit from this laser focus. Smart waste spotting, process mapping, and careful measurement turn good operations into great ones.

More sectors jump on the lean bandwagon every year, each finding clever ways to tackle their unique challenges. Smart companies see the writing on the wall – lean principles pave the way to lower costs, higher quality, and happier customers. That’s a future worth betting on.